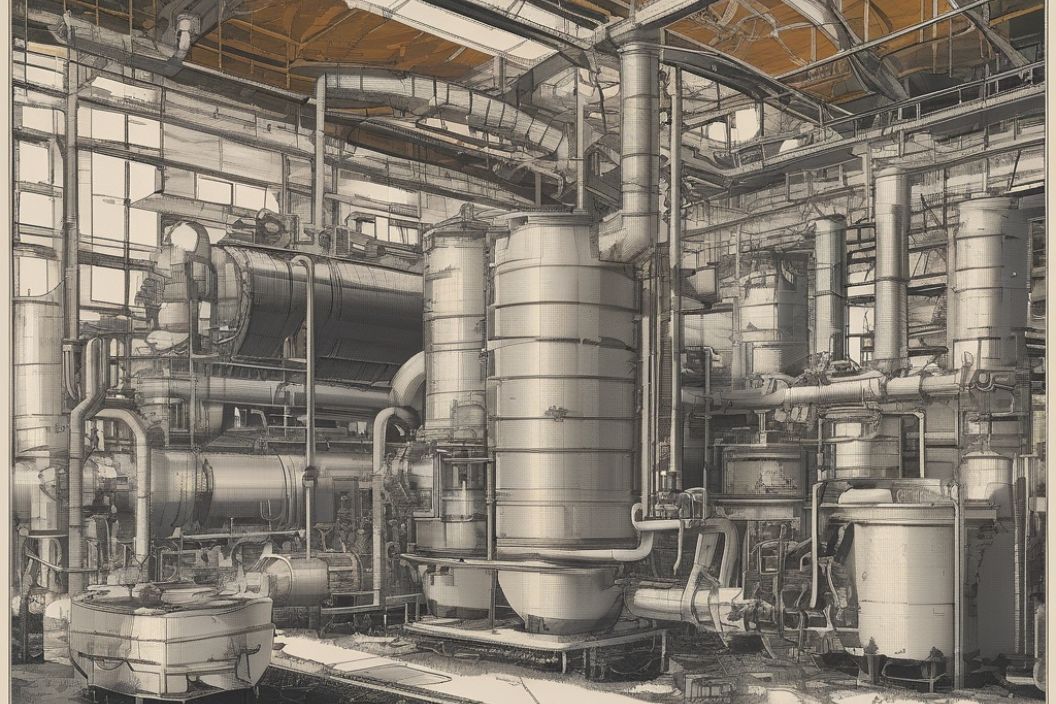

The chemical process industry (CPI) is integral to modern society, producing a vast array of products that support numerous sectors. However, this industry also generates significant amounts of waste, which poses environmental and economic challenges. Effective waste management and recycling are crucial for minimizing the environmental impact of chemical processing and enhancing sustainability. In this blog, we will explore the importance of waste management in the CPI, key strategies for managing and recycling waste, and innovative approaches that are driving the industry towards a more sustainable future.

The Importance of Waste Management in the Chemical Process Industry

Waste management in the CPI is vital for several reasons:

- Environmental Protection: Proper waste management prevents pollution, conserves natural resources, and protects ecosystems.

- Regulatory Compliance: Adhering to waste management regulations helps companies avoid fines, legal actions, and reputational damage.

- Resource Efficiency: Recycling and reusing waste materials reduce the need for raw materials, conserving natural resources and lowering costs.

- Sustainability Goals: Implementing effective waste management practices aligns with corporate sustainability goals and enhances social responsibility.

Types of Waste in the Chemical Process Industry

The CPI generates various types of waste, including:

- Solid Waste: Includes spent catalysts, sludges, filter cakes, and packaging materials.

- Liquid Waste: Comprises wastewater, spent solvents, and chemical residues.

- Gaseous Waste: Emissions from chemical reactions, such as volatile organic compounds (VOCs) and greenhouse gases.

Key Strategies for Waste Management and Recycling

Effective waste management and recycling in the CPI involve a combination of strategies to minimize waste generation, recover valuable materials, and ensure safe disposal. Key strategies include:

1. Source Reduction

Source reduction involves minimizing waste generation at the source. This can be achieved through:

- Process Optimization: Improving process efficiency to reduce waste generation.

- Green Chemistry: Designing chemical processes that produce less waste and use non-toxic materials.

- Material Substitution: Replacing hazardous materials with safer, more sustainable alternatives.

2. Recycling and Reuse

Recycling and reusing waste materials can significantly reduce the environmental impact of chemical processing. Key approaches include:

- Material Recovery: Recovering valuable materials from waste streams for reuse in the production process.

- Solvent Recycling: Reclaiming and purifying spent solvents for reuse, reducing the need for fresh solvents.

- Catalyst Regeneration: Regenerating spent catalysts to restore their activity and extend their lifespan.

3. Waste Treatment

Waste treatment involves processing waste materials to reduce their volume, toxicity, and environmental impact. Common treatment methods include:

- Physical Treatment: Methods such as filtration, sedimentation, and centrifugation to separate and remove contaminants.

- Chemical Treatment: Using chemical reactions to neutralize, precipitate, or detoxify hazardous waste.

- Biological Treatment: Employing microorganisms to degrade organic waste in processes such as bioremediation and composting.

4. Energy Recovery

Energy recovery involves converting waste materials into energy through processes such as:

- Incineration: Burning waste to generate heat and electricity while reducing waste volume.

- Gasification: Converting waste into syngas (a mixture of hydrogen and carbon monoxide) for use as a fuel or chemical feedstock.

- Anaerobic Digestion: Breaking down organic waste in the absence of oxygen to produce biogas, which can be used for energy production.

5. Safe Disposal

When waste cannot be recycled or treated, it must be disposed of safely to prevent environmental contamination. Safe disposal methods include:

- Landfilling: Disposing of solid waste in engineered landfills designed to contain and isolate waste from the environment.

- Deep Well Injection: Injecting liquid waste into deep geological formations to isolate it from groundwater and surface water.

- Secure Containment: Storing hazardous waste in secure containers and facilities to prevent leaks and contamination.

Innovations in Waste Management and Recycling

The CPI is continuously evolving, with new innovations enhancing waste management and recycling practices. Some of the latest advancements include:

1. Advanced Separation Technologies

Advanced separation technologies improve the efficiency of material recovery and waste treatment. Examples include:

- Membrane Filtration: Using semi-permeable membranes to separate and purify waste streams.

- Electrodialysis: Using electric fields to separate charged particles from waste streams.

- Supercritical Fluid Extraction: Employing supercritical fluids to selectively extract valuable components from waste.

2. Circular Economy Approaches

Circular economy approaches focus on designing processes that promote recycling, reuse, and resource efficiency. This includes:

- Industrial Symbiosis: Collaborating with other industries to use waste materials as inputs for their processes, creating a closed-loop system.

- Product Life Cycle Management: Designing products with end-of-life considerations to facilitate recycling and reduce waste generation.

3. Digitalization and Data Analytics

Digital technologies and data analytics enhance waste management by providing real-time monitoring, predictive insights, and optimization capabilities. Key applications include:

- IoT Sensors: Using sensors to monitor waste generation, composition, and treatment processes in real time.

- Predictive Analytics: Analyzing data to predict waste generation trends and optimize waste management practices.

- Digital Twins: Creating virtual models of waste management systems to simulate and optimize processes.

4. Biotechnological Solutions

Biotechnology offers innovative solutions for waste treatment and recycling, such as:

- Genetically Engineered Microorganisms: Developing microorganisms with enhanced capabilities to degrade or transform waste materials.

- Enzyme-Based Processes: Using enzymes to catalyze specific reactions for waste treatment and material recovery.

Key Takeaways

Effective waste management and recycling are essential for minimizing the environmental impact of the chemical process industry and achieving sustainability goals. By implementing strategies such as source reduction, recycling, waste treatment, energy recovery, and safe disposal, companies can reduce waste generation, recover valuable materials, and ensure environmental protection. Innovations in advanced separation technologies, circular economy approaches, digitalization, and biotechnology are driving the industry towards more sustainable waste management practices.

As the chemical process industry continues to innovate and adopt sustainable waste management practices, it will play a crucial role in addressing environmental challenges and promoting a more sustainable future. By prioritizing waste management and recycling, the CPI can enhance its operational efficiency, reduce costs, and contribute to global sustainability efforts.